Climeon has completed factory acceptance testing (FAT) for its HeatPower 300 waste heat recovery system, clearing the way for delivery to Zhejiang Xinle Shipbuilding Co. in China for installation on a new methanol dual-fuel cement carrier being built for NovaAlgoma Cement Carriers (NACC).

The system has been certified by classification society RINA for onboard installation, marking the first integration of Climeon’s HeatPower technology on a bulk carrier and the first approval of the HeatPower 300 by both a new shipowner and an additional classification society.

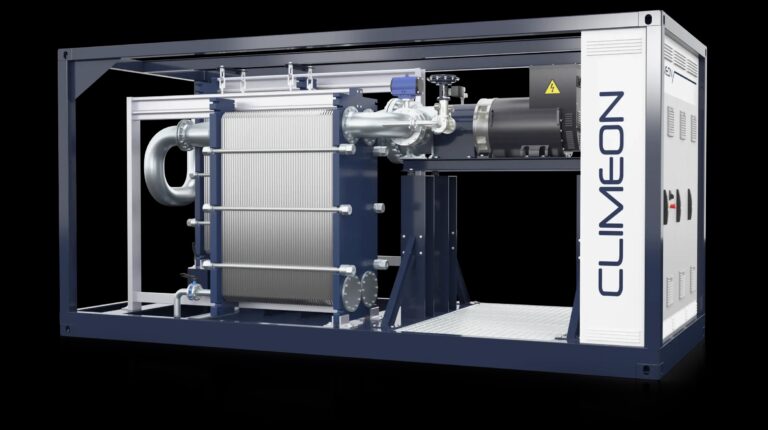

HeatPower 300 converts low-temperature waste heat from a vessel’s main engine into electricity, generating up to 300kW of power that can be used on board. Climeon says the system is intended to improve overall energy efficiency while reducing fuel consumption and emissions.

RINA attended the FAT in its role as classification society and on behalf of the shipowner, confirming that the system complies with applicable class rules, safety standards and documentation requirements for installation and operation.

With certification complete, the unit is now being prepared for shipment to Zhejiang Xinle Shipbuilding Co. in January. Installation is planned during 2026 in line with the vessel’s construction schedule.

The HeatPower 300 integration has been developed in cooperation between Climeon, NACC and the shipyard to align the system with the vessel’s design and performance requirements.

“Reaching this FAT milestone is an important step for the project and demonstrates that our HeatPower 300 meets all requirements and expectations from a new shipowner as well as an additional marine classification society,” said Lena Sundquist, CEO of Climeon. “We appreciate the trust placed in us and look forward to contributing to improved energy efficiency on NACC’s new vessel.”

In related news, ABB and HDF Energy partner to develop high-power fuel cell systems for large seagoing vessels