Technology group Wärtsilä will supply an integrated hybrid propulsion solution for three new self-discharging cargo vessels being built at the Royal Bodewes shipyard in the Netherlands for Norwegian shipowner Aasen Shipping.

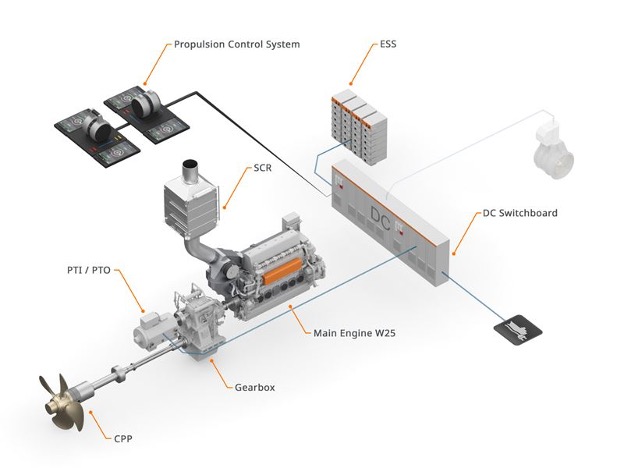

Each 9,500 DWT vessel will operate with one six-cylinder Wärtsilä 25 main engine fitted with a Wärtsilä NOX reduction system, a Wärtsilä gearbox and controllable pitch propeller with shaft line, a Wärtsilä Pro-Touch bridge control system, the Hybrid system with DC hub and 620kWh battery capacity, the control system, as well as the battery, power and energy management systems. The order was booked by Wärtsilä in September 2023 and the equipment is scheduled for delivery to Royal Bodewes in December 2025 and in 2026.

Wärtsilä delivered a similar hybrid propulsion solution to two earlier Aasen Shipping vessels, the Aasfoss and Aasfjell. These ships have successfully operated with the hybrid propulsion solution for almost two years, which has been cited as a prime consideration in the award of the new contract. To cater to the increasing demand for hybrid integrated machinery solutions, Wärtsilä works closely with customers such as Aasen Shipping from the early stages of a new-build project to optimize the performance and efficiency of the vessel and de-risk the project in the design phase.

Aasen Shipping’s CEO, Torbjørn Torkelsen, said, “We have been very satisfied with Wärtsilä’s support and close cooperation in helping us to achieve more efficient and cleaner cargo transport. This is important to us. Plus, the Wärtsilä engines are made ready for us to switch later to sustainable fuels, which will allow us to significantly further reduce carbon emissions in line with our fleet decarbonization aims.”

Stefan Nysjö, vice president of power supply at Wärtsilä Marine Power, commented, “We are delighted to have received this repeat order for our hybrid solution. The combination of the highly efficient and flexible Wärtsilä 25 engine with batteries provides both optimized operations and environmental sustainability. The ships can use electrical battery power when in the harbor and for low-load operations, and then switch to the main engines for transit. We look forward to continuing our collaboration with both Aasen Shipping and Royal Bodewes on our shared commitment to decarbonizing marine operations.”

Johan Tiemersma, project manager at Royal Bodewes, added, “As we understand that becoming emission-free is the biggest challenge of our generation, our focus at Royal Bodewes is to build innovative, sustainable and cost-efficient vessels for the industry. We are proud to be working alongside Aasen Shipping and Wärtsilä to utilize technology and solutions that will ensure these new self-discharging cargo vessels are able to cut emissions and reduce fuel costs whilst keeping carbon costs to a minimum.”

For more key equipment and services updates from the electric and hybrid marine technology industry, click here.