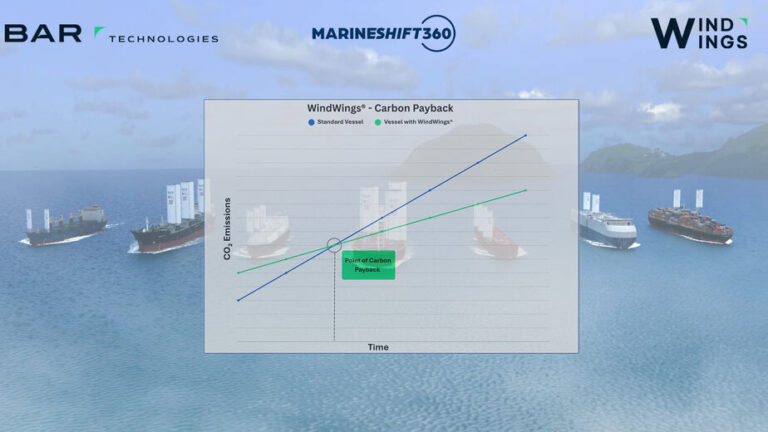

The MarineShift360 project has announced results from the recently concluded Impact Accelerator program, including the outcomes of BAR Technologies’ lifecycle assessment of its WindWings system – confirming that the system achieves a carbon payback in under six months.

The 10-month Impact Accelerator program applies advanced lifecycle assessment to drive sustainability in marine design and supply chains.

The analysis demonstrated that the WindWings system, which is already reducing fuel consumption by an average of 1.5 tons per wing per day (cutting CO2 emissions by 4.7 tons daily on global shipping routes) offsets its embedded carbon emissions in operational use in less than half a year – providing important context for assumptions about the carbon cost of maritime innovation.

“This is a landmark moment for commercial wind propulsion,” said John Cooper, CEO of BAR Technologies. “To demonstrate a sub-six-month carbon payback shows that WindWings is not only delivering immediate environmental benefit but is a commercially ready solution that meets the industry’s urgent decarbonization needs.”

“Seeing the payback come out in months has validated our design approach,” said Will Hopes, simulation and performance engineer at BAR Technologies. “WindWings are designed to decarbonize shipping as quickly as possible, and the study shows that this is what they are doing. LCA is a core part of every design review, not a separate consideration.”

The LCA, conducted in line with ISO 14044 standards, revealed that metalwork contributes the largest share of embedded emissions (44%), prompting BAR Technologies to pivot procurement toward recycled-content DH32 steel produced via Electric Arc Furnace processes. Additional carbon reductions are being achieved by increasing tooling utilization and revising composite layups.

“This wasn’t just a validation exercise,” added Cooper. “It enhanced engineering reviews, procurement decisions, and customer conversations. We have embedded carbon literacy across every function, because sustainable performance must be measurable, verifiable, and repeatable.”

In related news, Chemship to reduce emissions with MMT vessel optimization systems